Description

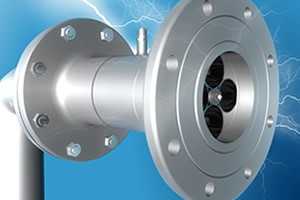

Turbine flow meter bearings ensure meter accuracy and operational longevity. Flow meters provide replicable and exact measure of linear, nonlinear or volumetric flow rate of a liquid or a gas. Turbine flow meters, or axial turbines, translate the rotating turbine action around an axis into a readable rate of flow. These types of meters are typically used for oil and gas measurement in pipelines where the density of the fluid depends greatly upon pressure, temperature and the gas composition.

To ensure a long life for flow meters it is crucial that the meter has been installed with the proper bearing material depending on the fluid lubricity and operating temperature. Many turbine meter installers prefer ceramic bearings for their superior design and durability. Ceramic bearings are a substantial upgrade over traditional steel bearings for many turbine flow meter environments. Ceramic is a non-porous, glass like surface so it is virtually frictionless and therefore needs very little or no lubrication to operate. Ceramic is also ideal for extremely high or low temperature applications with ranges of -100°C to +900°C (-148°F to +1652°F.)

Boca Bearings has a full range of bearings and balls in a variety of materials such as stainless steel, alumina oxide ceramic, silicon nitride ceramic and heavy duty plastics. Many different styles of bearings are also available including radial deep groove bearings, thrust bearings and angular contact bearings. Additionally, bearing configurations can often be tailored to fit each application comprising variations of materials for races, retainers and balls as well as specialty lubrications and coatings.

Check out our whitepaper: The Ultimate Guide to Full Ceramic Bearings in Water Processing, Water Filtration, and Liquid Handling