Crossfire 3D Printed Quadcopter Part 4

Crossfire 3D Printed Quadcopter Part 4

Mar 10, 2017

Cory Oliver

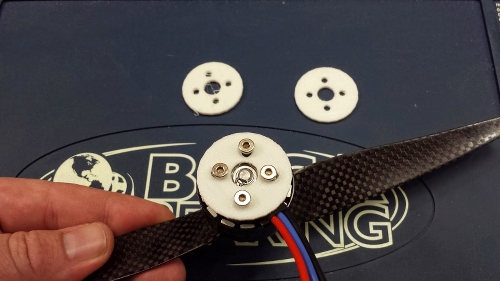

One of the things that came up with my test print, was that the screw holes on the ends of the arms did not match up with the screw holes on the motors I got.

Not to worry, though. The designer has provided the SketchUp files for all the parts on the quad, so that adjustments to the files can be made. SketchUp is a free, easy to use design program.

http://www.sketchup.com/

If you've never used it before, there are some great tutorial videos to help you get started...

http://www.sketchup.com/learn

I loaded the the arm into SketchUp and moved the holes around to where I needed them. To see whether or not I had them in the right place, I didn't want to print an entire arm, so I took just the surface with the screw holes in it, copied it to a separate file, made it 2mm thick and printed a small disk that I could test with my motors. It's a good thing I did that, I printed about 4 of these disks before I finally got it right. The screw holes positions in the motors are not exactly uniform, and I ended up making the holes slightly oval shaped.

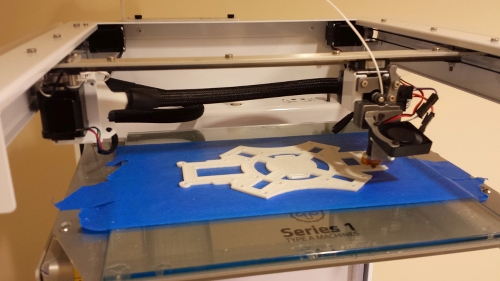

I also went ahead a printed a new bottom plate, since the white PLA that we have is really good quality.

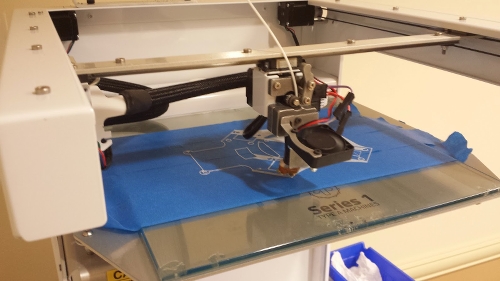

Now that the bottom plate is done, I've got a print going of a top plate that has the screw holes in the right position for the KK2 flight controller.

This is the file I used for the top plate, since it was the only top plate I found that seems like it won;t give me problems when I try to mount my flight controller: http://www.thingiverse.com/thing:151821

I'm going to keep on printing parts, keeping the printer going almost non-stop. We are supposed to get some new PLA colors in tomorrow, so I'll most likely be able to start printing the arms, which I plan to do in black. I also got some hardware in to test the electronics. (servo cables, EC5 connectors, etc)

Stay tuned.

Tags

Archives

-

2021

-

2021

- 2020

-

2019

- ASV Part 7

- Pin Ball Machine Part 5

- Football Thrower Part 8

- Pinball Machine Part 4

- Pinball Machine Part 3

- Bottle Car Part 3

- Toy Car Power Wheels Part 4

- ASV Part 6

- Pinball Machine Part 2

- Football Thrower Part 7

- Pinball Machine

- Football Thrower Part 6

- Toy Car Power Wheels Part 3

- Football Thrower Part 5

- ASV Part 4

- Football Thrower Part 4

- Football Thrower Part 3

- ASV Part 3

- ASV Part 2

- Wire Bender Project

- Football Thrower Part 2

- ASV (Automated Surface Vehicle)

- Toy Car Power Wheels Vid

- Football Thrower

- Toy Car Power Wheels Part 2

- Toy Car Power Wheels

- Bottle Car Part 2

- Time Lapse

- Bottle Racer Launcher

- Shirogorov Multi Row Bearing System Disassembly

- Candy Sorter - Project Update 4

- Candy Sorter Project - Update 3

- Candy Sorter Project - Update 2

- Wire Bender Project - Part 1

- Solar Panel Light Tracking Project: Update 3

- Candy Sorter Project - Update 1

-

2018

- Solar Panel Light Tracking Project: Update 2

- Solar Panel Light Tracking Project: Update 1

- Workshop Weekly Update 19: Maker Faire Preparation

- Lew's Speed Spool Upgraded with Boca Bearings

- Project Rocket League - Part 1

- RC Boat Project: Update 9

- RC Boat Project: Update 8

- Power Wheels Racer 2.0: Update 4

- Autonomous Submarine Project: Part 5

- RC Boat Project: Update 7

- Autonomous Submarine Project: Part 4

- How to prepare for an F1 in Schools Competition with Team Divignite

- Autonomous Submarine Project: Part 3

- 3D Printed Ford Flathead V8 Engine Working Model

- Autonomous Submarine Project: Part 2

- RC Boat Project: Update 6

- Autonomous Submarine Project: Part 1

- Power Wheels Racer 2.0: Update 3

- RC Boat Project: Update 5

- Workshop Weekly Update 18: Submarine Hull

- RC Boat Project: Update 4

- Workshop Weekly Update 17: Power Wheels Racer Steering

- RC Boat Project: Update 3

- Boca Bearings Workshop Weekly Update 16

- RC Boat Project: Update 2

- Pi Zero Drone Part 9: Calibrating ESC Manually

- Boca Bearings Workshop Weekly Update 15

- Pi Zero Drone Part 8: On board Instrument Calibration

- Power Wheels Racer 2.0: Update 2

- Boca Bearings Workshop Weekly Update 14

- RC Boat Project: Update 1

- Power Wheels Racer 2.0: Update 1

- Electric Skateboard Project Update 2

- Boca Bearings Workshop Weekly Update 13

- RC Boat Introduction

- Autonomous Submarine Introduction

- Power Wheels Racer Part 15: Post-Race Update

- Power Wheels Racer Part 14: Updates Before Maker Faire

- Penn US 113W Fishing Reel Upgraded with Boca Bearings

- Power Wheels Racer: Part 13

- Pi Zero Drone Post 7: Modular Body

- Nano Blade QX2 Repairs

- Pi Zero Drone 6: After First Flight and Mods

- Pi Zero Drone Part 5: Testing...

- Fitbit Cheat-O-Matic 2: 3D Printed Mechanical Simplicity (Intro)

- Power Wheels Racer Part 12: Updates and fixes

- Pi Zero Drone Part 4: Calibrations

- SECME Mouse Trap Car Racing

- Virtual Reality R/C Car: Part 5

- The Pi Zero Drone Part 3: Connecting the PXFmini

- Virtual Reality R/C Car: Part 4 Adding The Head Tracker

- Racing Power Wheels Part 11: Fixing the Caster for Stable Steering

- The Pi Zero Drone Part 2: Construction of the Frame

- Virtual Reality R/C Car Part 3

- 3D Printed Camaro LS3 V8 Engine

- Iron Man Helmet Project - Part 1

- F1 in Schools - Bearing and Wheel Design

- Virtual Reality R/C Car Part 2

- Virtual Reality R/C Car Part 1

- Racing Power Wheels Part 10: New Hydraulic Brake System

- The Pi Zero Drone Part 1: Introduction

- Racing Power Wheels Part 9: Demonstration, Test Run, and Steering Problems

- Racing Power Wheels Part 8: The Brakes, Problems Encountered, and Sparks Resolved

- Racing Power Wheels Part 7: Setting up the Steering

- Boca Bearings Workshop Weekly Update 12

- Racing Power Wheels Part 6: Motor Testing, Controller, and Sparks

- Racing Power Wheels Part 5: The Rear Axle and Parts

- Racing Power Wheels Part 4: Project Update on the Motor Kit and Batteries

- Flytanium Butterfly Knife Bearing Tolerance Comparison

- Racing Power Wheels Part 3: Selecting Sprocket Size and Calculating Speed

- Functional Jet Turbine Project Part 1

- Racing Power Wheels Part 2: Axle, Rear Wheels, Brakes, and Sprockets

- Boca Bearings Workshop Weekly Update 11

- Zero Tolerance 0808 Folding Knife Bearing Upgrade

- Boca Bearings on a HOPE EVO 2 Hub Set

- Wave Energy Senior Design Project

- Boca Bearings Workshop Weekly Update 10

- 3D Printed Robotic Hand: Part 8 - The Wiring Diagram of the Hand and Codes for Adafruit Servo Shield

- Racing Power Wheels Part 1: The Dune Racer and Motor Kit Selection

- Game of Drones Hiro Airframe Quadcopter Part 1: Building the Quadcopter

- Boca Build 2.0 Geared Sliding Puzzle: Final Fabrication

- Boca Build 2.0 Geared Sliding Puzzle: Control Box

- Boca Bearings Workshop Weekly Update 9

- Traxxas XO-1: Boca Bearings Install

- SeaTech and Boca Bearings

- Ryworx Omeme Butterfly Knife Bearing Walkthrough

- 3D Printed Robotic Hand: Part 7 - The Last Codes Used (No Servo Shield Required)

- Simple Robotic Arm Made Out of Cardboard Pieces - Part 2: How to make it

- Boca Bearings Innovation Series: Acavallo Carousel

- Autonomous Rover Part 6: Troubleshooting

- Boca Bearings Innovation Series: Primal 2 Speedbike

- Boca Bearings Innovation Series: Human Powered Helicopter - Gamera

- Boca Build 2.0 Geared Sliding Puzzle Part 4: Clutch

- Boca Bearings Workshop Weekly Update 8

- Boca Bearings Workshop Weekly Update 7

- Autonomous Rover Part 5: Using the ArduPilot Mega(APM) and GPS

- Boca Bearings Workshop Weekly Update 6

- Boca Build 2.0 Geared Sliding Puzzle Part 3: Fabrication Details

- DIY Stunt Wire System - Part 2

- DIY Stunt Wire System - Part 1

-

2017

- Boca Build 2.0 Geared Sliding Puzzle Part 2: Fabrication

- Maker Faire Orlando 2017 - Part 2

- Maker Faire Orlando 2017 - Part 1

- The Drone Scene in South Florida

- Boca Build 2.0 Geared Sliding Puzzle Part 1: Design

- Traxxas TQi Telemetry Radio and App: Part 4 - Car Run and Performance

- Hybridized Garrett Boca Bearings Turbine - Part 3

- Amundson TCP450 Fishing Reel Bearing Installation

- Simple Robotic Arm Made Out of Cardboard Pieces

- Autonomous Rover Part 4: Finishing Up the Build and Some Demonstration

- 1/10th Scale Replica 1984 CJ7 Jeep

- Vintage Tool Box 3D Printed: Part 4 - Final Details

- Autonomous Rover Part 3: Building the Frame

- Hybridized Garrett Boca Bearings Turbine - Part 2

- Vintage Tool Box 3D Printed: Part 3 - Testing and Refining

- Vintage Toolbox 3D Printed: Part 2 - Construction and Fabrication

- Hybridized Garrett Boca Bearings Turbine - Part 1

- Boca Bearings Workshop Weekly Update 5

- Traxxas TQi Telemetry Radio and App: Part 3 - Telemetry Setup and Testing

- Autonomous Rover Part 2: The MINDS-i 4X4 3-in-1 Robot and the FlySky FS-T6 Transmitter

- Vintage Toolbox 3D Printed: Part 1 - Design and Research

- Autonomous Rover Part 1: Project Proposal

- Para-Athlete Alfonso Garibay Jr.

- Traxxas TQi Telemetry Radio and App: Part 2 - Bearings Replacements

- 3D Printed Robotic Hand: Part 6 - More Programming and Debugging

- 3D Printed Robotic Hand: Part 5 - Programming and Debugging

- Aermacchi Crank Alignment and Balancing Tool

- Boca Bearings Workshop Weekly Update 4

- 3D Scanner Project Update 1

- Boca Bearings Workshop Weekly Update 3

- RC Car Project - Update 3

- Boca Bearings Workshop Weekly Update 2

- Modified Bike Project: Part 4 - The Bike

- Boca Bearings Workshop Weekly Update 1

- Upgrading Jigging Master Ocean Devil PE5 with Boca Bearings

- 3D Printed Robotic Hand: Part 4 - The 3D Printed Hand Build

- Arduino Robot Project: Part 5 - Video Demonstration

- 3D Printed Robotic Hand: Part 3 - The Glove Build

- New and Expanded Inventory of Mounted Unit Bearings

- 3D Printed Robotic Hand: Part 2 - Pre-build

- Boca Bearings on Shimano XTR Wheels

- Quantum Vapor Bearing Upgrade

- RC Car Project - Update 2

- Boca Bearings Fidget Spinner Collection Competition

- Zerobot Project - Update 3

- Zerobot Project - Update 2

- Introducing Miami artist maker and robot sculptor Jorge Roldan

- 3D Printed Robotic Hand: Part 1 - Project Proposal

- Traxxas TQi Telemetry Radio and App

- Modified Bike Project: Part 3 - Engine build

- Arduino Robot Project: Part 4 - Shield and Software

- Blade 180 CFX Helicopter: Part 2 - First Repair

- Arduino Robot Project: Part 3 - Building the Parts of the Line Robot

- Arduino Robot Project: Part 2 - Pre-Build

- Zeorbot Project - Update 1

- The World's Largest 3D Printed Fidget Spinner

- Blade 180 CFX Helicopter Introduction

- 3D Printer Filament Stand Project

- Zerobot Project Introduction

- Arduino Robot Project: Part 1 The Sensor Board

- Boca Bearings Mavic Cosmic Carbones

- Scan-O-Tron Project: Kinect Attached

- Modified Bike Project: Part 2 Frame Set Up

- Okuma Krios KS 273W Bearing Comparison

- eMerge Americas 2017

- Boca Bearings 3D Printed Spinner Competition

- Avet HXW Raptor Ceramic Bearing Upgrade

- Electric Skateboard Project Update 1

- ELB Pro Flipper Butterfly Knife Bearing Upgrade

- RC Car Project Update

- Making 3D-Printed Fidget Spinners

- Fidget Spinner Bearing Spin Time Comparison

- Marine Robotics Club Introduction

- Modified Bike Project: Part 1 1976 Cimmato City Bike

- Peacock Bass Fishing In South Florida

- How to Install Bearings in Mavic Crossmax SL Wheels

- 3D Printed Robotic Hand Project Revisision

- How to Install Bearings in a THM Carbones Clavicula Crankset

- Scan-o-tron project: Building accessories

- Bloomer Tree Kinetic Artwork Donation, Damage, Repair and Relocation

- Electric Skateboard Project Introduction

- Line Roller Bearing Replacement Shimano Symetre 4000RI

- How to change the bearings in a Shimano Citica 200D

- Scan-o-tron Project Introduction

- How to change the bearings in a Shimano Chronarch CI4+

- Maker Faire Miami

- Sketch Bot Project Update 1

- How to change the bearings in a Shimano Curado 50e

- Boca Bearings Releases Expanded Inventory of Ceramic Hybrid Bearings

- X-Carve Vacuum Attachment

- Crossfire 3D Printed Quadcopter Part 7

- Boca Bearings Releases New Ceramic Hybrid Go Series

- Crossfire 3D Printed Quadcopter Part 6

- Sketch Bot Project Update

- Crossfire 3D Printed Quadcopter Part 5

- Sponsored Racer: Kevin Thomas, 2017 Palmetto Classic - Race Report

- Boca Bearing's Guide for Fidget Spinners

- Crossfire 3D Printed Quadcopter Part 4

- Crossfire 3D Printed Quadcopter Part 3

- Crossfire 3D Printed Quadcopter Part 2