RC Boat Project: Update 3

RC Boat Project: Update 3

Jul 31, 2018

Ryan Kwaterski

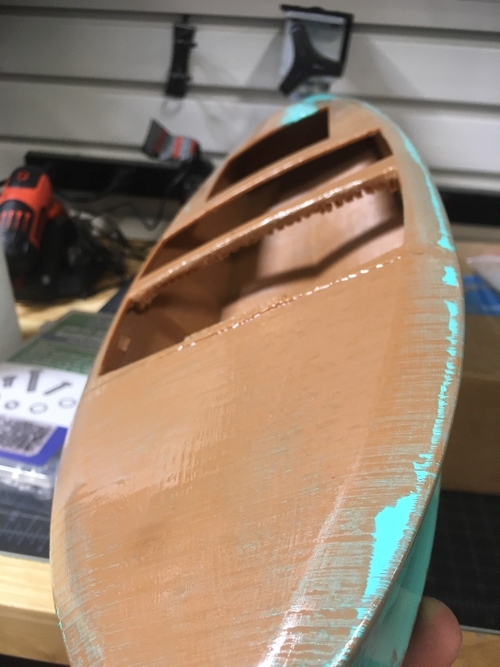

This week was a busy week of resurfacing the vessel. Using XTC-3D as seen in figure 1 the bottom of the hull was resurfaced. This product is specifically designed to fill in small holes and imperfections from the 3D printing process.

Figure 1: XTC-3D applied to bottom of the hull.

You simply use a small dish or cup and thoroughly mix in 2 parts XTC-3D yellow with 1 part XTC-3D blue (latex gloves should be worn during the mixing and application process). A little goes a long way with this product and should be applied in a very thin layer. The “self-leveling” characteristics make applying it very easy and effective. After the bottom of the hull was dry, the boat was flipped right-side up and the top was then coated in the same product as seen in figure 2. The drying time is about 2 hours and dries glossy, which is the perfect look I was going for. Once it was dry it was time to give it a light sanding with P220. The XTC-3D was applied, let stand to dry, then sanded a total of 3 times in order to get the boat to a smooth mirror like finish.

Figure 2: Top of boat after XTC-3D was dry.

Tags

Archives

-

2021

-

2021

- 2020

-

2019

- ASV Part 7

- Pin Ball Machine Part 5

- Football Thrower Part 8

- Pinball Machine Part 4

- Pinball Machine Part 3

- Bottle Car Part 3

- Toy Car Power Wheels Part 4

- ASV Part 6

- Pinball Machine Part 2

- Football Thrower Part 7

- Pinball Machine

- Football Thrower Part 6

- Toy Car Power Wheels Part 3

- Football Thrower Part 5

- ASV Part 4

- Football Thrower Part 4

- Football Thrower Part 3

- ASV Part 3

- ASV Part 2

- Wire Bender Project

- Football Thrower Part 2

- ASV (Automated Surface Vehicle)

- Toy Car Power Wheels Vid

- Football Thrower

- Toy Car Power Wheels Part 2

- Toy Car Power Wheels

- Bottle Car Part 2

- Time Lapse

- Bottle Racer Launcher

- Shirogorov Multi Row Bearing System Disassembly

- Candy Sorter - Project Update 4

- Candy Sorter Project - Update 3

- Candy Sorter Project - Update 2

- Wire Bender Project - Part 1

- Solar Panel Light Tracking Project: Update 3

- Candy Sorter Project - Update 1

-

2018

- Solar Panel Light Tracking Project: Update 2

- Solar Panel Light Tracking Project: Update 1

- Workshop Weekly Update 19: Maker Faire Preparation

- Lew's Speed Spool Upgraded with Boca Bearings

- Project Rocket League - Part 1

- RC Boat Project: Update 9

- RC Boat Project: Update 8

- Power Wheels Racer 2.0: Update 4

- Autonomous Submarine Project: Part 5

- RC Boat Project: Update 7

- Autonomous Submarine Project: Part 4

- How to prepare for an F1 in Schools Competition with Team Divignite

- Autonomous Submarine Project: Part 3

- 3D Printed Ford Flathead V8 Engine Working Model

- Autonomous Submarine Project: Part 2

- RC Boat Project: Update 6

- Autonomous Submarine Project: Part 1

- Power Wheels Racer 2.0: Update 3

- RC Boat Project: Update 5

- Workshop Weekly Update 18: Submarine Hull

- RC Boat Project: Update 4

- Workshop Weekly Update 17: Power Wheels Racer Steering

- RC Boat Project: Update 3

- Boca Bearings Workshop Weekly Update 16

- RC Boat Project: Update 2

- Pi Zero Drone Part 9: Calibrating ESC Manually

- Boca Bearings Workshop Weekly Update 15

- Pi Zero Drone Part 8: On board Instrument Calibration

- Power Wheels Racer 2.0: Update 2

- Boca Bearings Workshop Weekly Update 14

- RC Boat Project: Update 1

- Power Wheels Racer 2.0: Update 1

- Electric Skateboard Project Update 2

- Boca Bearings Workshop Weekly Update 13

- RC Boat Introduction

- Autonomous Submarine Introduction

- Power Wheels Racer Part 15: Post-Race Update

- Power Wheels Racer Part 14: Updates Before Maker Faire

- Penn US 113W Fishing Reel Upgraded with Boca Bearings

- Power Wheels Racer: Part 13

- Pi Zero Drone Post 7: Modular Body

- Nano Blade QX2 Repairs

- Pi Zero Drone 6: After First Flight and Mods

- Pi Zero Drone Part 5: Testing...

- Fitbit Cheat-O-Matic 2: 3D Printed Mechanical Simplicity (Intro)

- Power Wheels Racer Part 12: Updates and fixes

- Pi Zero Drone Part 4: Calibrations

- SECME Mouse Trap Car Racing

- Virtual Reality R/C Car: Part 5

- The Pi Zero Drone Part 3: Connecting the PXFmini

- Virtual Reality R/C Car: Part 4 Adding The Head Tracker

- Racing Power Wheels Part 11: Fixing the Caster for Stable Steering

- The Pi Zero Drone Part 2: Construction of the Frame

- Virtual Reality R/C Car Part 3

- 3D Printed Camaro LS3 V8 Engine

- Iron Man Helmet Project - Part 1

- F1 in Schools - Bearing and Wheel Design

- Virtual Reality R/C Car Part 2

- Virtual Reality R/C Car Part 1

- Racing Power Wheels Part 10: New Hydraulic Brake System

- The Pi Zero Drone Part 1: Introduction

- Racing Power Wheels Part 9: Demonstration, Test Run, and Steering Problems

- Racing Power Wheels Part 8: The Brakes, Problems Encountered, and Sparks Resolved

- Racing Power Wheels Part 7: Setting up the Steering

- Boca Bearings Workshop Weekly Update 12

- Racing Power Wheels Part 6: Motor Testing, Controller, and Sparks

- Racing Power Wheels Part 5: The Rear Axle and Parts

- Racing Power Wheels Part 4: Project Update on the Motor Kit and Batteries

- Flytanium Butterfly Knife Bearing Tolerance Comparison

- Racing Power Wheels Part 3: Selecting Sprocket Size and Calculating Speed

- Functional Jet Turbine Project Part 1

- Racing Power Wheels Part 2: Axle, Rear Wheels, Brakes, and Sprockets

- Boca Bearings Workshop Weekly Update 11

- Zero Tolerance 0808 Folding Knife Bearing Upgrade

- Boca Bearings on a HOPE EVO 2 Hub Set

- Wave Energy Senior Design Project

- Boca Bearings Workshop Weekly Update 10

- 3D Printed Robotic Hand: Part 8 - The Wiring Diagram of the Hand and Codes for Adafruit Servo Shield

- Racing Power Wheels Part 1: The Dune Racer and Motor Kit Selection

- Game of Drones Hiro Airframe Quadcopter Part 1: Building the Quadcopter

- Boca Build 2.0 Geared Sliding Puzzle: Final Fabrication

- Boca Build 2.0 Geared Sliding Puzzle: Control Box

- Boca Bearings Workshop Weekly Update 9

- Traxxas XO-1: Boca Bearings Install

- SeaTech and Boca Bearings

- Ryworx Omeme Butterfly Knife Bearing Walkthrough

- 3D Printed Robotic Hand: Part 7 - The Last Codes Used (No Servo Shield Required)

- Simple Robotic Arm Made Out of Cardboard Pieces - Part 2: How to make it

- Boca Bearings Innovation Series: Acavallo Carousel

- Autonomous Rover Part 6: Troubleshooting

- Boca Bearings Innovation Series: Primal 2 Speedbike

- Boca Bearings Innovation Series: Human Powered Helicopter - Gamera

- Boca Build 2.0 Geared Sliding Puzzle Part 4: Clutch

- Boca Bearings Workshop Weekly Update 8

- Boca Bearings Workshop Weekly Update 7

- Autonomous Rover Part 5: Using the ArduPilot Mega(APM) and GPS

- Boca Bearings Workshop Weekly Update 6

- Boca Build 2.0 Geared Sliding Puzzle Part 3: Fabrication Details

- DIY Stunt Wire System - Part 2

- DIY Stunt Wire System - Part 1

-

2017

- Boca Build 2.0 Geared Sliding Puzzle Part 2: Fabrication

- Maker Faire Orlando 2017 - Part 2

- Maker Faire Orlando 2017 - Part 1

- The Drone Scene in South Florida

- Boca Build 2.0 Geared Sliding Puzzle Part 1: Design

- Traxxas TQi Telemetry Radio and App: Part 4 - Car Run and Performance

- Hybridized Garrett Boca Bearings Turbine - Part 3

- Amundson TCP450 Fishing Reel Bearing Installation

- Simple Robotic Arm Made Out of Cardboard Pieces

- Autonomous Rover Part 4: Finishing Up the Build and Some Demonstration

- 1/10th Scale Replica 1984 CJ7 Jeep

- Vintage Tool Box 3D Printed: Part 4 - Final Details

- Autonomous Rover Part 3: Building the Frame

- Hybridized Garrett Boca Bearings Turbine - Part 2

- Vintage Tool Box 3D Printed: Part 3 - Testing and Refining

- Vintage Toolbox 3D Printed: Part 2 - Construction and Fabrication

- Hybridized Garrett Boca Bearings Turbine - Part 1

- Boca Bearings Workshop Weekly Update 5

- Traxxas TQi Telemetry Radio and App: Part 3 - Telemetry Setup and Testing

- Autonomous Rover Part 2: The MINDS-i 4X4 3-in-1 Robot and the FlySky FS-T6 Transmitter

- Vintage Toolbox 3D Printed: Part 1 - Design and Research

- Autonomous Rover Part 1: Project Proposal

- Para-Athlete Alfonso Garibay Jr.

- Traxxas TQi Telemetry Radio and App: Part 2 - Bearings Replacements

- 3D Printed Robotic Hand: Part 6 - More Programming and Debugging

- 3D Printed Robotic Hand: Part 5 - Programming and Debugging

- Aermacchi Crank Alignment and Balancing Tool

- Boca Bearings Workshop Weekly Update 4

- 3D Scanner Project Update 1

- Boca Bearings Workshop Weekly Update 3

- RC Car Project - Update 3

- Boca Bearings Workshop Weekly Update 2

- Modified Bike Project: Part 4 - The Bike

- Boca Bearings Workshop Weekly Update 1

- Upgrading Jigging Master Ocean Devil PE5 with Boca Bearings

- 3D Printed Robotic Hand: Part 4 - The 3D Printed Hand Build

- Arduino Robot Project: Part 5 - Video Demonstration

- 3D Printed Robotic Hand: Part 3 - The Glove Build

- New and Expanded Inventory of Mounted Unit Bearings

- 3D Printed Robotic Hand: Part 2 - Pre-build

- Boca Bearings on Shimano XTR Wheels

- Quantum Vapor Bearing Upgrade

- RC Car Project - Update 2

- Boca Bearings Fidget Spinner Collection Competition

- Zerobot Project - Update 3

- Zerobot Project - Update 2

- Introducing Miami artist maker and robot sculptor Jorge Roldan

- 3D Printed Robotic Hand: Part 1 - Project Proposal

- Traxxas TQi Telemetry Radio and App

- Modified Bike Project: Part 3 - Engine build

- Arduino Robot Project: Part 4 - Shield and Software

- Blade 180 CFX Helicopter: Part 2 - First Repair

- Arduino Robot Project: Part 3 - Building the Parts of the Line Robot

- Arduino Robot Project: Part 2 - Pre-Build

- Zeorbot Project - Update 1

- The World's Largest 3D Printed Fidget Spinner

- Blade 180 CFX Helicopter Introduction

- 3D Printer Filament Stand Project

- Zerobot Project Introduction

- Arduino Robot Project: Part 1 The Sensor Board

- Boca Bearings Mavic Cosmic Carbones

- Scan-O-Tron Project: Kinect Attached

- Modified Bike Project: Part 2 Frame Set Up

- Okuma Krios KS 273W Bearing Comparison

- eMerge Americas 2017

- Boca Bearings 3D Printed Spinner Competition

- Avet HXW Raptor Ceramic Bearing Upgrade

- Electric Skateboard Project Update 1

- ELB Pro Flipper Butterfly Knife Bearing Upgrade

- RC Car Project Update

- Making 3D-Printed Fidget Spinners

- Fidget Spinner Bearing Spin Time Comparison

- Marine Robotics Club Introduction

- Modified Bike Project: Part 1 1976 Cimmato City Bike

- Peacock Bass Fishing In South Florida

- How to Install Bearings in Mavic Crossmax SL Wheels

- 3D Printed Robotic Hand Project Revisision

- How to Install Bearings in a THM Carbones Clavicula Crankset

- Scan-o-tron project: Building accessories

- Bloomer Tree Kinetic Artwork Donation, Damage, Repair and Relocation

- Electric Skateboard Project Introduction

- Line Roller Bearing Replacement Shimano Symetre 4000RI

- How to change the bearings in a Shimano Citica 200D

- Scan-o-tron Project Introduction

- How to change the bearings in a Shimano Chronarch CI4+

- Maker Faire Miami

- Sketch Bot Project Update 1

- How to change the bearings in a Shimano Curado 50e

- Boca Bearings Releases Expanded Inventory of Ceramic Hybrid Bearings

- X-Carve Vacuum Attachment

- Crossfire 3D Printed Quadcopter Part 7

- Boca Bearings Releases New Ceramic Hybrid Go Series

- Crossfire 3D Printed Quadcopter Part 6

- Sketch Bot Project Update

- Crossfire 3D Printed Quadcopter Part 5

- Sponsored Racer: Kevin Thomas, 2017 Palmetto Classic - Race Report

- Boca Bearing's Guide for Fidget Spinners

- Crossfire 3D Printed Quadcopter Part 4

- Crossfire 3D Printed Quadcopter Part 3

- Crossfire 3D Printed Quadcopter Part 2